See below for calculations. The pressure drop seen in heat exchangers with leakage flows and horizontal baffles is much higher than that in exchangers with leakage flows and vertical baffles.

Numerical Simulation Of The Effect Of Baffle Cut And Baffle Spacing On Shell Side Heat Exchanger Performance Using Cfd

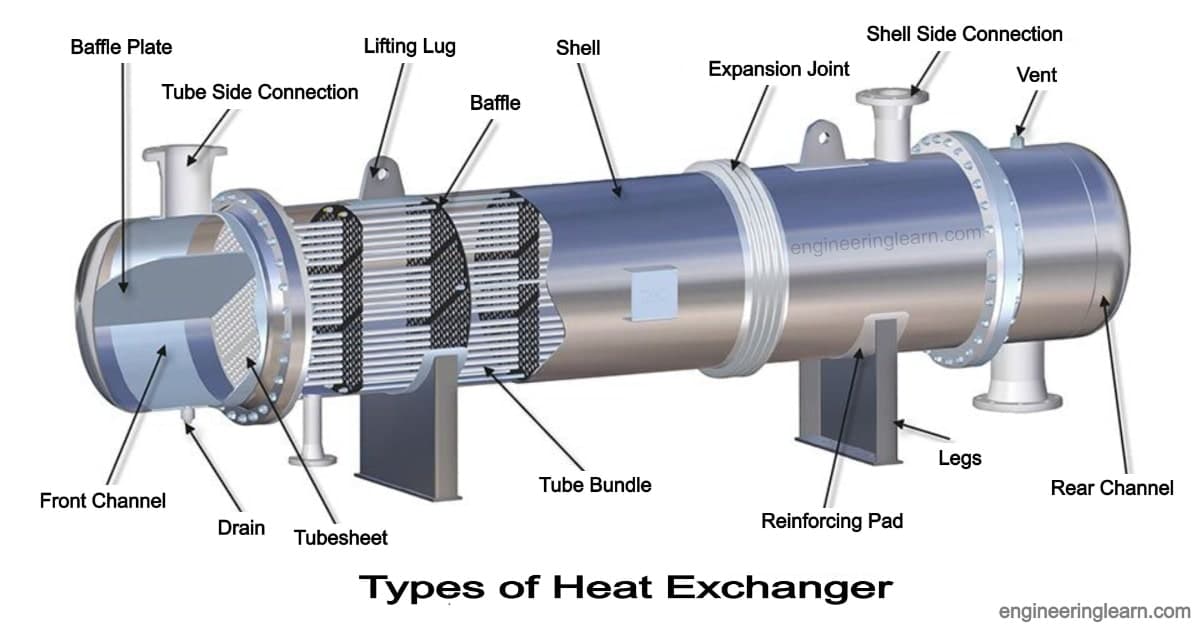

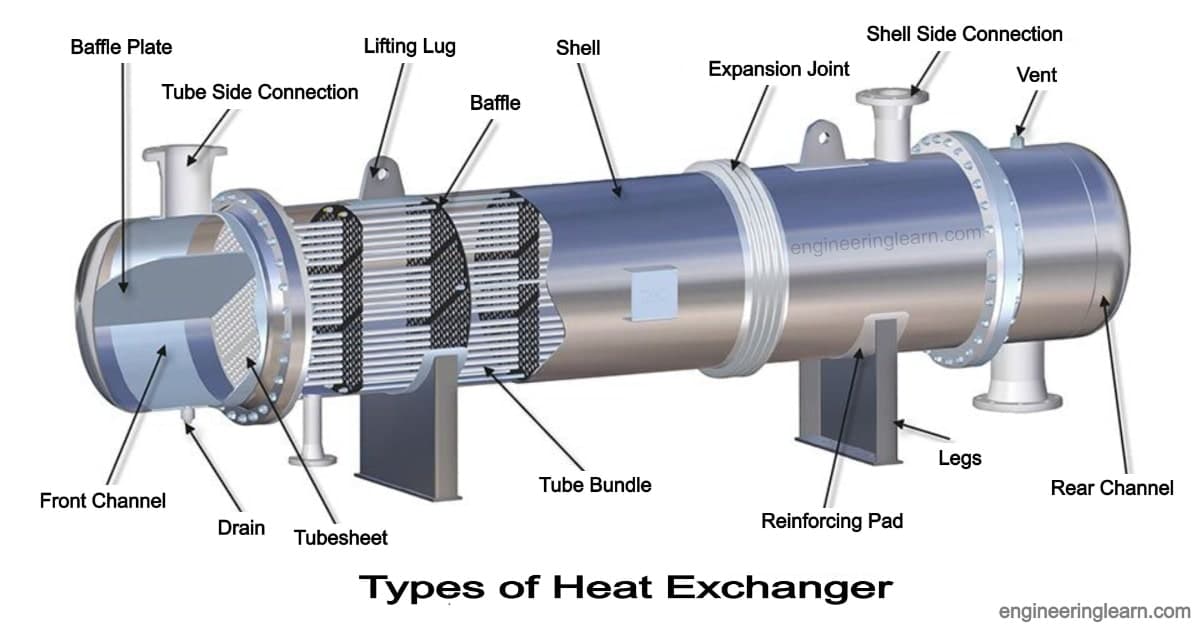

Typical parts and connections shown in Figures 12 13and 14IS.

. Baffles are an integral part of the shell and tube heat exchanger design. So if for example we have a shell diameter of 356 mm 14 inch then the minimum baffle spacing selected should be between 1068 mm 42 inch to 178 mm 7 inch. SA-240 Grade 304 Plate.

SA-240 Grade 304 Plate. Structural Design Of Heat Exchanger. Most plate heat exchangers use the single pass design.

These fluids never encounter each other due to being separated by the heat exchanger. Generally for liquids a value of 0507 kgcm2is permitted per shell. Guide the liquid through the tube.

Bin Gao Qincheng Bi Miao Gui 1 Experimental performance comparison for. Removable U-tube heat exchanger 1. 4503-1967 are summarized below.

The thermal analysis of helical baffle heat exchanger using this method give us clear. The baffle pitch and baffle cut are selected during the heat exchanger design to yield the highest fluid velocity and heat transfer rate while respecting the allowable pressure drop. Baffle plate with holes to fit around the tubes of a heat exchanger has tubes of a non-uniform cross-section so that an annular contact exists between the plate and the tube at the narrowest part.

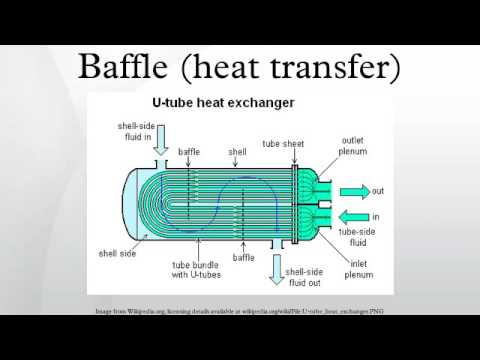

This causes the fluid to move up and down. SA-240 Grade 304 Plate. One of the cornerstones of an effective design for a shell-and-tube exchanger is ideal flow on the shellside of the heat exchanger which is largely controlled by the baffle specifications.

Dezhen Chen in Design and Operation of Heat Exchangers and their Networks 2020 5222 Bell-Delaware method In the shell side the segmental plate baffles make the flow pattern very complex. Designs and manufactures a wide range of heat exchangers for refrigeration industrial and special applications Our evaporators and condensers can be manufactured with different. The baffle cut should be horizontal when the shell side heat transfer is sensible heating or cooling with no phase change.

03 356 mm 1068 mm 42 inch To 05 356 mm 178 mm 7 inch. A baffle is designed to support tube bundles and direct the flow of fluids for maximum efficiency. The tubular heat exchanger consists of a housing a heat transfer tube bundle a pipe plate a baffle baffle and a tubing.

The Heat Exchange Design Handbook contains two chapters discussing these factors. Baffle plate is a plate or mechanical device designed to restrain or regulate the flow of a fluid. Tubesheets less than 100 mm thick are generally made from plate material.

The shell-and-tube heat exchangers with helical baffles consist of the cylinder heat-transfer tubes and baffles. Minimum baffle spacing is generally one-fifth of the shell diameter and not less than 508 mm 2 in. Function of Baffle Plates.

Baffles Baffles are components of shell and tube heat exchangers which are used to support. Provide Support for the tubes Prevent any vibration Maintains the spacing between the tubes Helps in efficient cooling Plate Heat. This is a very important parameter for heat exchanger design.

Ahigher pressure drop is usually war- ranted for viscous. A plate heat exchanger is used to transfer heat energy from one fluid to another. The shell diameter of heat exchanger is 250 mm and 2500 mm in.

Single and Multi-Pass Design Flow Types Flow through a plate heat exchanger may be parallel cross or counter. The minimum baffle spacing is the greater of 508 mm or one fifth of the inner shell diameter. The model contains 7 Copper tubes each having 20 mm external diameter and 17 mm internal diameter length 600 mm and inner diameter of steel shell is 90 mm and outer.

As such for shell and. Since Kern method used in design of heat exchangers with a baffle cut of 25 fixed. The maximum baffle spacing is dependent on material and size of tubes.

Maximum baffle spacing is limited by the requirement to provide adequate.

5 Types Of Heat Exchanger Definition Parts And Application Complete Guide Engineering Learn

The Shape Of Three Heat Exchangers A Graphical Model Of Segmental Download Scientific Diagram

Baffles In Heat Exchangers Webbusterz Engineering

Baffle Plate For Heat Exchanger Epcsteel Com

Optimizing Shell Side Baffle Spacing Enggcyclopedia

How Do Baffles Increases The Heat Transfer Rate In A Shell And Tube Heat Exchanger Quora

0 comments

Post a Comment